The Challenge: New Location, Inadequate Crates

As companies focus on improving supply chains to optimize inventory, delivery costs, and speed to market, changes in process often pose new problems for their packaging plan. In this case, a major long-haul truck manufacturer was making major changes to its parts distribution model, adding new stress to the industrial crates used for storage and shipping.

The company changed to a centralized warehousing model, receiving parts in bulk from all over the world to be repackaged and stored in one mega-warehouse in the central US. The parts covered a wide range of sizes from small and light, to large and heavy. Items included everything from gear boxes to rub strips, hydraulic struts and torsion rods. The parts are stored so spare parts for over-the-road heavy trucks are at the ready.

The repackaged parts, in standard order quantities, were stored in high-count stacks in high-rise racks for weeks or months before shipment. The central US location, while providing an upside in freight delivery costs, had the downside of being very humid. Existing corrugated packaging, weakened by the humidity, was not strong enough to handle the high stacking for long periods in the humid environment.

Failing packages required repackaging for shipment, more than doubling the budgeted cost for those packages and slowing down the entire shipment process. Safety was becoming a major concern—as the corrugated packaging could fail to a degree that a heavy part fell out of the racks onto a worker.

The Solution: Industrial Shipping Crates

The truck manufacturer quickly charged a team of engineers and buyers to consider new options for industrial crates:

- Corrugated Crates – Increasing the corrugated test strength would increase the cost across the board—and the team believed the same failure issues caused by moisture would still occur over time.

- Wood Crates – While stronger than corrugated, wood would cause major increases in packaging and freight costs.

- Hybrid Crates – Hybrid designs were considered with a mix of wood and corrugated—but were thought to add complexity to the packaging supply chain and with the same cost and failure issues.

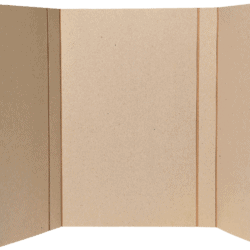

- Laminated Paperboard – The unique properties of high-strength laminated paperboard, and its lack of fluting, offered more durability than corrugated. The DuraCrate design combined high-strength papers with a unique grooving process.

This option quickly became the leading candidate to solve the issues.

Why DuraCrate Laminated Paperboard Packaging Works

A team from Dura-Fibre immediately began producing samples in various sizes with a range of thicknesses and thereby strengths. Early top-to-bottom compression results looked promising to the truck manufacturer.

The customer then determined DuraCrate industrial crates were the optimal solution for their business. The unique properties of laminated paperboard, and its lack of moisture-attracting fluting, offered more durability than corrugated. While Dura-Fibre’s capability to provide exterior water-resistant coating wasn’t necessary, it provided comfort that the humidity and moisture damage problems would be solved.

DuraCrate was also much lower cost than wood. Additionally, there were unplanned benefits in space savings because DuraCrate remains flat until ready for use, requiring less storage space required by prebuilt wood crates.

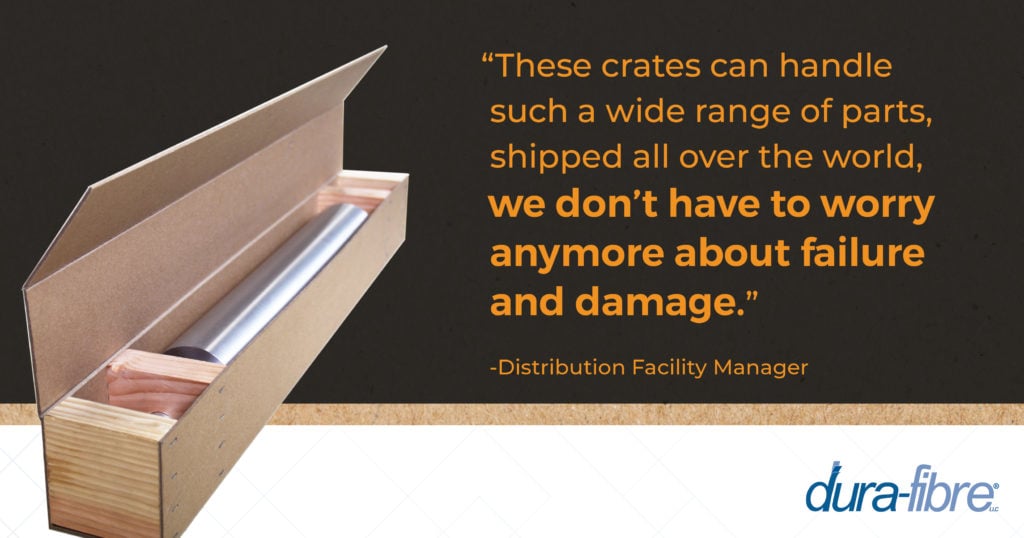

“ We had to make a change and Dura-Fibre kept working with us to find the right approach for our situation,” said the team leader and Warehouse Manager of the truck company. “These crates can handle such a wide range of parts, shipped all over the world, we don’t have to worry anymore about failure and damage.”

Laminated Paperboard Shipping Crates: Stronger than Cardboard, Lighter than Wood

DuraCrate has multiple truck, recreational vehicle and construction equipment customers – as well as many customers in piping and tubing, window fashions, specialty instruments, and a long list of industries. Each use case has its differences and unique challenges. From the product to the process, shipping or end-customer requirements, Dura-Fibre’s packaging engineers partner in the design process to meet each customer’s unique needs.

DuraCrate heavy-duty industrial shipping crates, constructed from extra tough laminated paperboard and engineered with the strongest groove available, allow customers to save on packaging cost and freight costs while reducing damage and increasing end-customer satisfaction.

To learn more about Dura-Fibre laminated paperboard industrial crates, please complete the form below.

Save money, space and damage.

Fill out the form below to get started today!

Foam Padded Board

Foam Padded Board Unitized Book Board

Unitized Book Board Laminated Binders Board

Laminated Binders Board Laminated Graphic Board

Laminated Graphic Board Push-Pull Sheets

Push-Pull Sheets Tier Sheets

Tier Sheets Slip Sheets - Single Ply and Laminated

Slip Sheets - Single Ply and Laminated Pallet Sheets

Pallet Sheets Pads - Single Ply and Laminated

Pads - Single Ply and Laminated Poly Coated Paperboard

Poly Coated Paperboard Furniture Back Panels

Furniture Back Panels Trash Compactor Boxes

Trash Compactor Boxes Paperboard Drywall Shims

Paperboard Drywall Shims Paperboard Totes and Containers

Paperboard Totes and Containers Paperboard Crates

Paperboard Crates Paperboard Wraps

Paperboard Wraps Paperboard Cartons

Paperboard Cartons Paperboard Strap Protectors

Paperboard Strap Protectors Paperboard Covers

Paperboard Covers High Caliper C1S and C2S

High Caliper C1S and C2S Heavyweight Folding Boxboard

Heavyweight Folding Boxboard Heavyweight Thru White

Heavyweight Thru White