Curious about what paperboard is, or wondering how to use it?

We’re here to answer your frequently asked questions about paperboard.

What is paperboard?

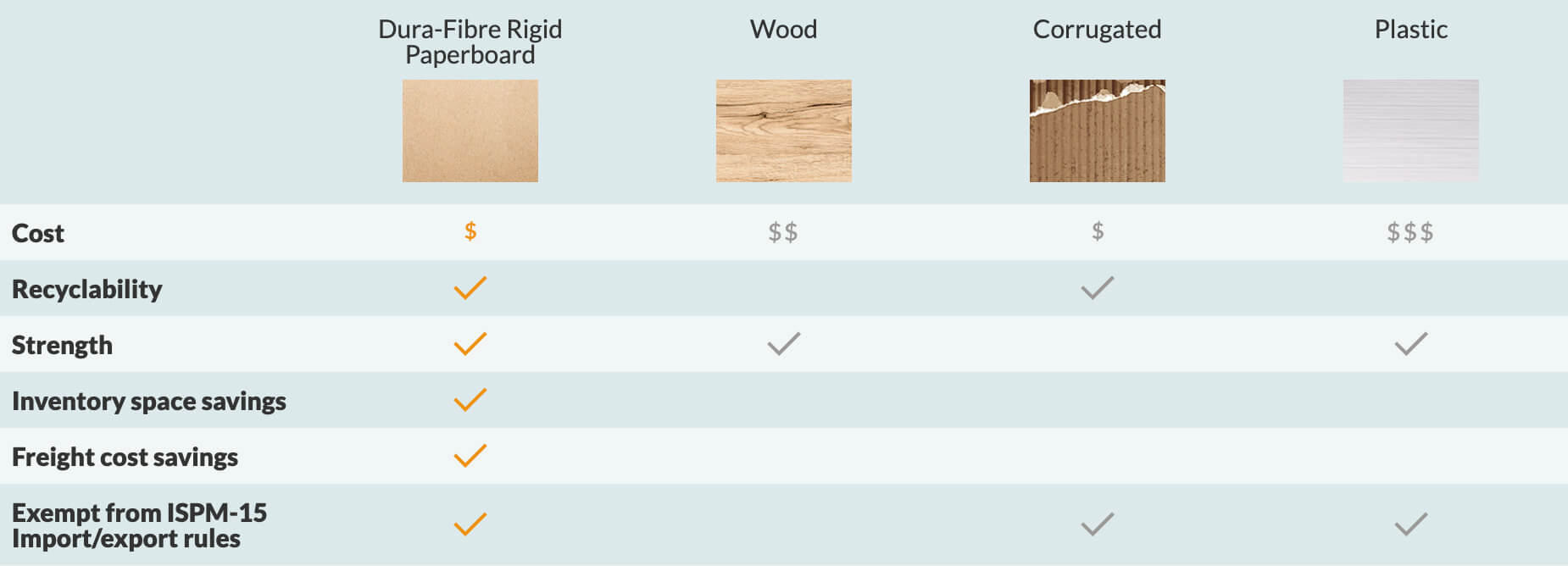

Paperboard is a thick, paper-based material. While there is no single differentiator between paper and paperboard, paperboard is usually over 0.012 in, or 12 points, thick, making it generally thicker than paper. Paperboard can be a single-ply paper made from a paper mill, or multi-ply via the process of laminating (gluing) multiple plies together. Paperboard is primarily used when consumers need material that is both foldable and rigid. Laminated paperboard can be made of many kinds of papers—each with their own attributes and accompanying strengths— including both recycled and newly produced papers. Regardless of the material used to create it, paperboard packaging is inherently renewable and recyclable, making it an environmentally friendly choice.

What are advantages of paperboard?

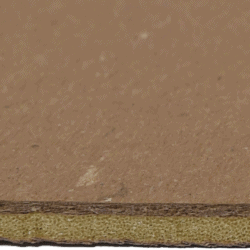

Heavy paperboard is very cost effective and is strong and flexible—making it ideal for applications such as packaging cartons. Paperboard is strong and tough, especially relative to its weight. It can even replace wood in industrial crating applications. Paperboard is superior to corrugated cardboard, in use cases when burst and tear damage overwhelm the fluting design of corrugated. Paperboard is usually made with recycled papers and is always recyclable, making it one of the most sustainable materials in the world, and much more sustainable than plastic options. It is also very printable, and the top surfaces used in multi-ply laminated paperboard offer a wide range of possibilities. Multi-print on coated packaging is what the best brands in the world use to protect their products.

What is the difference between cardboard and paperboard?

Currently, naming conventions are not standardized across the paper industry, and as a result, paper market customers sometimes use terms that are interchangeable. The term “cardboard” is used to describe paper, paperboard, and corrugated products. Here is a comparison breakdown of each product:

– Paperboard is thicker paper. Watch to see how it compares to cardboard.

– Laminated paperboard is thicker paper made from multiple plies.

– Corrugated is made from multiple plies of paper, including at least one ply which has been mechanically fluted, giving it the distinctive waves in the middle.

What is paperboard used for?

Paperboard is amazingly flexible, making it a pro at taking on many roles: Strong packaging, rigid folding cartons, industrial crates, protective sheets, heavy duty totes, furniture components and many other specialty applications. Laminated paperboard meets so many needs because it can be made using a wide array of papers. For example, paperboard can have a coated outside, making it a good choice for printing, or a high-caliper inside, making it tough and thick. The possibilities in paper, matched with the wide range of manufacturing capabilities, make for an endless list of possibilities. Paperboard can replace metals, wood, plastics and glass, and can be the primary outer packaging or can be an integral part of the internal packaging.

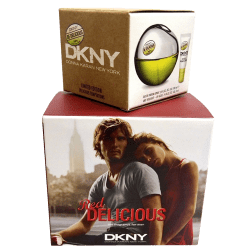

Can I print on paperboard?

Absolutely. Paperboard is the primary packaging you see in stores, meaning all the designs you see as a customer, ranging from simple printing to amazing multi-color graphics, are possible with paperboard packaging. This includes products on every aisle, including electronics, cosmetics, beverages, dry goods, and pharmacy items. Even very thick paperboard is highly printable, such as what you see in club stores, where high-quantity packaging is the preferred choice. Even paperboard crating can have printing, ranging from a simple part number up to multi-color brand markings. There are few limits when it comes to printing technology.

What is a slip sheet?

The term “slip sheets” can have multiple meanings. Slip sheets are pieces of single-ply thin paper used on the bottom, middle and top of layers of product or layers of packaging. The term can also be used to refer to laminated paperboard made from multiple plies of high-strength linerboard, cut and scored with exact specifications, to replace wood pallets and skids, with the use of sophisticated push-pull attachments replacing the forks on a lift truck. Using slip sheets to replace pallets can save material costs, labor, freight and damage. Slip sheets are especially helpful in beverage markets, bottles, cans, and containers, consumer goods, e-commerce, industrial goods, processed food, protein, shipping and distribution, fruit and vegetable, and many other markets. Paperboard is especially adaptable for these applications because the strength requirements of the laminated paperboard can be adjusted to meet the needs of the load weight, and coatings are available to help with slip and moisture resistance.

Still have questions or interested in getting a quote?

If you’re still wondering, “What is paperboard?” after reading our answers to frequently asked questions, or want to get started on your next project, we’re happy to help. Contact us today.

Foam Padded Board

Foam Padded Board Unitized Book Board

Unitized Book Board Laminated Binders Board

Laminated Binders Board Laminated Graphic Board

Laminated Graphic Board Push-Pull Sheets

Push-Pull Sheets Tier Sheets

Tier Sheets Slip Sheets - Single Ply and Laminated

Slip Sheets - Single Ply and Laminated Pallet Sheets

Pallet Sheets Pads - Single Ply and Laminated

Pads - Single Ply and Laminated Poly Coated Paperboard

Poly Coated Paperboard Furniture Back Panels

Furniture Back Panels Trash Compactor Boxes

Trash Compactor Boxes Paperboard Drywall Shims

Paperboard Drywall Shims Paperboard Totes and Containers

Paperboard Totes and Containers Paperboard Crates

Paperboard Crates Paperboard Wraps

Paperboard Wraps Paperboard Cartons

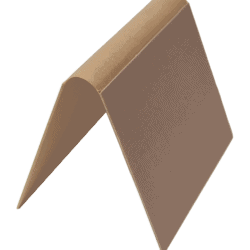

Paperboard Cartons Paperboard Strap Protectors

Paperboard Strap Protectors Paperboard Covers

Paperboard Covers High Caliper C1S and C2S

High Caliper C1S and C2S Heavyweight Folding Boxboard

Heavyweight Folding Boxboard Heavyweight Thru White

Heavyweight Thru White