As scrutiny grows over the use of plastics due to their environmental impact, companies in sectors like food & beverage, healthcare and medical, and consumer packaging face new challenges exporting products overseas.

Dura-Fibre recently met with one company that experienced a rejected shipment costing millions because it was packaging with plastic materials that its European partner could no longer accept. We helped it leverage laminated paperboard as an alternative so it could quickly return to business as usual. If you’re facing a similar challenge, contact us right away for help.

Even if you aren’t currently impacted by recent European restrictions, domestic policies might soon follow suit. Adapting now to replace custom plastic packaging with paperboard can help you future-proof, and it provides other benefits. Laminated paperboard is not only more sustainable but can also be more durable and affordable than packaging with plastic.

Paperboard Wins for Sustainability and Biodegradability

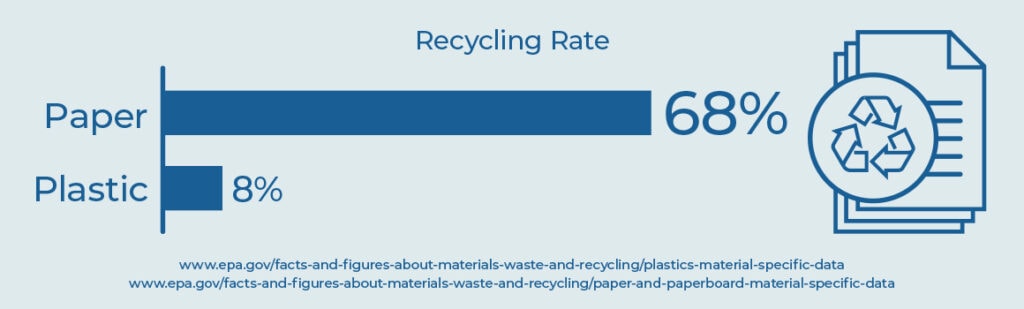

A major issue for plastics, and major benefit for paperboard, is environmental sustainability. Plastic is increasingly difficult to manage as a waste product. As restrictions continue to tighten, companies don’t want to be burdened by the challenge of recycling or reusing plastic packaging materials. By contrast, paperboard is much more easy to recycle and quickly decomposes – returning to fibers, whether on land or in water. Learn more about our commitment to protecting the Earth’s natural resources and our sustainable packaging solutions.

Affordability and Competitiveness of Paperboard as a Plastic Packaging Alternative

Plastics certainly haven’t become so widely used by accident. They are often the least expensive form of packaging and protection – even if not the best performer. One exception: Shorter runs put pressure on plastic product pricing – especially when expensive setup tooling is involved for the molds. Laminated paperboard tooling is much less expensive and often not even necessary, making it a fitting alternative to packaging with plastic.

Rigid Paperboard: Durable in Appearance and Performance

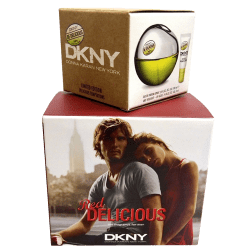

Rigid or thick paperboard has many advantages over custom plastic packaging (listed below), but with the need to attract attention, a big benefit is printing quality. It absorbs ink more uniformly – allowing clearer images. And the ability to slit and cut and score and shape – even thick or thin – just makes paperboard so much more versatile than plastics. Because rigid paperboard is thick, it maintains its appearance – even when used for heavy contents.

The common plastics, including Polyethylene (LDPE and HDPE), Polypropylene (PP), and Polyethylene Terephthalate (PET) are waterproof, versatile, and often low cost in large quantities. But, they are also prone to stress cracks, have low resistance to temperatures, deforming and losing their shape – where they got their name – and even flammable.

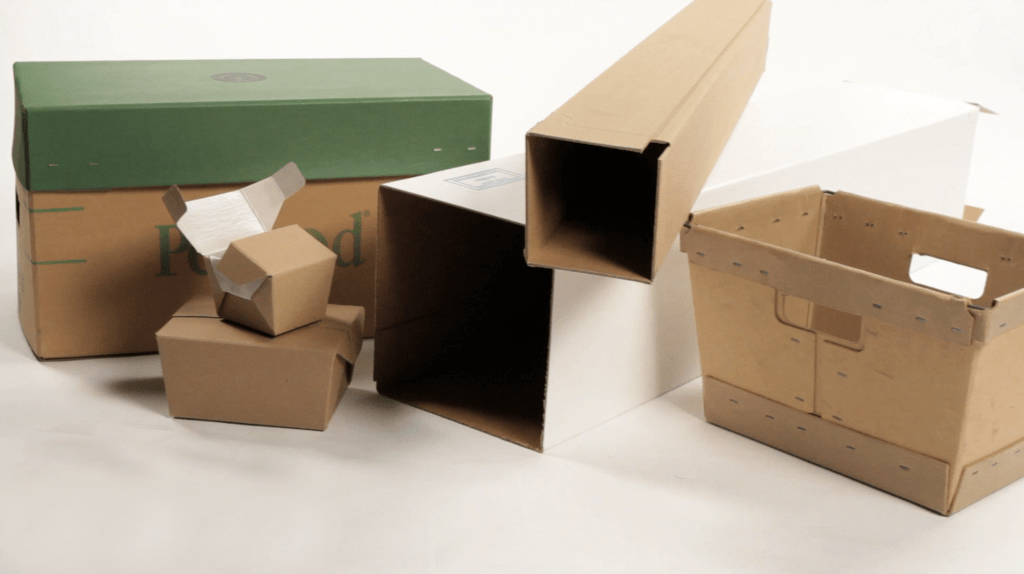

Paperboard Packaging Applications

Here are just some of the many products for which we’ve provided paperboard as an alternative to plastic packaging:

- Single use – safe for food cartons, boxes, slip sheets, and containers.

- Lightweight packaging – high tensile for consumer packaging, partitions, and signage.

- Heavyweight packaging – high bending strength great for crates, skid pads, and wood replacement.

- Efficient converting of low complexity products – low cost for high volumes such as folding

cartons, trays, pads, tier sheets, and sheathing. - Custom circumstances – intricate die-cuts and outer laminations such as for furniture components.

- Important UV and odor resistance – absorbing less for candies, dairy, and food products.

- Interior Packaging – Stiff and easily die-cut into special shapes for holding objects tightly in place such as for pharmaceuticals, medical devices, and manufacturing kitting of parts.

- Sound Dampening – a low-cost sound and environmentally sensitive sound reduction material.

Thick Paperboard Advantages Over Plastic Packaging

Beyond its natural properties, paperboard packaging offers a wide range of advantages over plastic packaging. Among the leading reasons to use thick paperboard:

- Biodegradable and non-toxic – Paperboard is completely biodegradable and non-toxic.

- Temperature sensitive – Holds products ranging from 400-degree glues to protecting frozen vaccines.

- Space saving – Ships and stores flat.

- Moisture resistance – Multiple coating options can be added to an already stable moisture barrier.

Put Paperboard Packaging to Work for Your Application

Have you already thought of a packaging application where laminated paperboard would be a good alternative to packaging with plastic? Or, would you like more information about how adapting your strategy to include paperboard can help future-proof your business? No matter the case, we are here and happy to answer your questions or provide you with a quote. Contact us today.

Foam Padded Board

Foam Padded Board Unitized Book Board

Unitized Book Board Laminated Binders Board

Laminated Binders Board Laminated Graphic Board

Laminated Graphic Board Push-Pull Sheets

Push-Pull Sheets Tier Sheets

Tier Sheets Slip Sheets - Single Ply and Laminated

Slip Sheets - Single Ply and Laminated Pallet Sheets

Pallet Sheets Pads - Single Ply and Laminated

Pads - Single Ply and Laminated Poly Coated Paperboard

Poly Coated Paperboard Furniture Back Panels

Furniture Back Panels Trash Compactor Boxes

Trash Compactor Boxes Paperboard Drywall Shims

Paperboard Drywall Shims Paperboard Totes and Containers

Paperboard Totes and Containers Paperboard Crates

Paperboard Crates Paperboard Wraps

Paperboard Wraps Paperboard Cartons

Paperboard Cartons Paperboard Strap Protectors

Paperboard Strap Protectors Paperboard Covers

Paperboard Covers High Caliper C1S and C2S

High Caliper C1S and C2S Heavyweight Folding Boxboard

Heavyweight Folding Boxboard Heavyweight Thru White

Heavyweight Thru White