The Challenge: Can Tier Sheet Manufacturers Lower Supply Chain Costs and Maintain Safety?

As companies look for second- and third-generation supply chain optimization, cost savings and operational improvements may seem difficult to find. As an engineered water solutions manufacturer discovered, partnering with tier sheet manufacturers on new packaging was one key area in which to wring out savings.

The manufacturing company – a maker of fixtures, faucets, valves and drains – was searching for cost savings. A staff member said, “How expensive is this wood we’re using in our pallet stacks?”

That was a good question.

The company manufactures heavy steel parts. They use pallets to efficiently move them within their plants and to their distribution centers. Among their requirements:

- The parts are heavy (often chrome plated) and awkwardly shaped. Weight and shape must be accounted for to prevent pallets from becoming unstable.

- Stacks must be in layers to prevent rubbing between parts and to allow efficient and safe stacking on the pallet.

- A certain amount of grip is needed to prevent the parts from sliding around. This helps prevent the unsafe falling of parts.

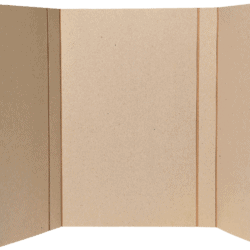

The manufacturing company was using a large volume of tier sheets (also known as divider sheets) to create these layers. The manufacturer used several sizes of tier sheets, all with rounded corners.

Though this was a simple part of their operation, annual tier sheet costs totaled hundreds of thousands of dollars. The potential for savings was real.

Paperboard Tier Sheets or Masonite® Hardboard

The company charged its corporate buyer with not only developing a list of additional hardboard suppliers and checking pricing competitiveness but also researching other options. Though the buyer found options to change hardboard suppliers, the buyer noted switching would not generate significant savings.

Based on the size and weight of the parts, corrugated slip sheets and cardboard solutions were easily ruled out due to the stiffness requirements.

A Google® search turned up a new option: Tier sheet supplier Dura-Fibre.

As tier sheet manufacturers, Dura-Fibre’s Technical Account Team began learning the company’s current process, key factors for success and the company’s must-have items. Among the findings:

- The hardboard was stronger than necessary.

- Optimization was possible by matching the hardboard tier sheet load strength using lighter tier sheet materials.

Testing the Tier Sheets Load Capacity of DuraSheet Industrial Tier Sheets

The engineered water solutions manufacturer was narrowing in on industrial tier sheets.

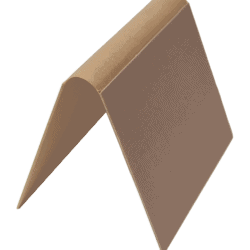

The solution: High-strength, thick, laminated paperboard sheets made of the finest kraft papers.

Now, came the test. The buyer involved operations contacts to take part in sampling and trials. To demonstrate DuraSheet strength, Dura-Fibre created samples that would support more than the load needed, then worked down to the optimum thickness and strength.

It was evident from the very beginning this change from hardboard to laminated paperboard was not only possible, but also would offer major cost savings. While materials costs represented one key area for supply chain optimization, savings also came in the form of freight. The company is weight-limited on its truckloads, so the lighter paperboard sheets also helped reduce freight costs.

As Dura-Fibre began producing samples in several thicknesses and pallet tier sheet load strengths for testing, another benefit emerged: Safety. DuraSheets are much lighter and therefore much easier to handle by the crews in the parts factory and distribution centers.

Tier Sheet Manufacturers Offer Customization

Dura-Fibre provided a range of options to the company, including:

- Die-cut corners and holes

- Moisture-resistant coatings

- Non-slip coatings

- Multiple print options

From these options, the company determined a non-skid coating was helpful, but opted for square corners to maximize stacking space.

With two sizes and two different strengths, a fourth benefit emerged: Storage space requirements are even less with DuraSheets than prior hardboard divider sheets. More DuraSheets fit per pallet, providing a major advantage in space-limited manufacturing facilities.

Due to the volume and multiple locations using the sheets, Dura-Fibre also provided just-in-time stocking service.

“We had used the wood dividers so long that people probably hadn’t thought it was even an option to change,” said the Regional General Manager “At first thought, paperboard doesn’t sound like it would be strong enough for what we do. But, Dura-Fibre was confident they could help and they were right.”

Paperboard Tier Sheets: Solution for Savings

As tier sheet manufacturers, Dura-Fibre produces high-strength paperboard sheets, constructed from extra tough paper, engineered to meet customer-specific requirements. That helped the engineered water solutions manufacturer find savings on packaging, while simultaneously reducing freight costs and maintaining safety. That’s just one example of why DuraSheets are used in a wide range of manufacturing, warehousing, and distribution end markets.

To learn more about Dura-Fibre laminated pallet tier sheets, please complete the form below.

Masonite® is a registered trademark of MASONITE CORPORATION, Tampa, Florida.

Foam Padded Board

Foam Padded Board Unitized Book Board

Unitized Book Board Laminated Binders Board

Laminated Binders Board Laminated Graphic Board

Laminated Graphic Board Push-Pull Sheets

Push-Pull Sheets Tier Sheets

Tier Sheets Slip Sheets - Single Ply and Laminated

Slip Sheets - Single Ply and Laminated Pallet Sheets

Pallet Sheets Pads - Single Ply and Laminated

Pads - Single Ply and Laminated Poly Coated Paperboard

Poly Coated Paperboard Furniture Back Panels

Furniture Back Panels Trash Compactor Boxes

Trash Compactor Boxes Paperboard Drywall Shims

Paperboard Drywall Shims Paperboard Totes and Containers

Paperboard Totes and Containers Paperboard Crates

Paperboard Crates Paperboard Wraps

Paperboard Wraps Paperboard Cartons

Paperboard Cartons Paperboard Strap Protectors

Paperboard Strap Protectors Paperboard Covers

Paperboard Covers High Caliper C1S and C2S

High Caliper C1S and C2S Heavyweight Folding Boxboard

Heavyweight Folding Boxboard Heavyweight Thru White

Heavyweight Thru White