Thick chipboard means multiple things to multiple people but as a chipboard manufacturer, we’re here to give you the facts, starting with the basics:

- The base paper is often referred to as “chip” – though the technical industry description is “uncoated recycled paperboard” – also known as “URB” (Yes, if you read that carefully, the acronym is confusing. One of the many names for thick chipboard is URB, which stands for uncoated recycled board.) – not URP, confused yet?

- Paper mills can make chip in various thicknesses – generally from 18pt (.018) to 45pt (.045).

- Laminated paperboard manufacturers, like Dura-Fibre, glue together multiple plies of chip to make thick paperboard, ranging from 20pt to 250pt.

- Thick chipboard is made from 100% recycled paper – and is fully recyclable again – making thick chipboard much more sustainable than plastics and wood.

Beyond the basics, the uses and benefits are endless and the applications vary widely, as shown in the few we highlight below.

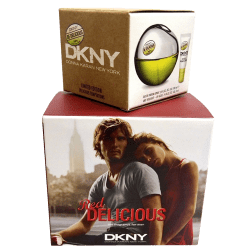

Set-up Boxes – Customized Rigidity

Thick paperboard in multiple calipers offers a wide range of capabilities to rigid folding cartons carrying high-end products such as jewelry, electronics, fragrances, and spirits. Thick chipboard sheets of various colors are wrapped with specialty papers, uniquely printed and embossed, to make one-of-a-kind packages.

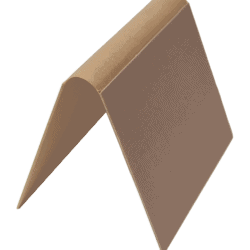

Crating – Cost Effective Beam Strength

Heavy-weight chipboard used in industrial crates replaces wood – reducing costs for materials, assembly labor, and shipping weight. Beam strength and puncture resistance greatly outperform corrugated cardboard. Logo printing adds branding impact and moisture resistance adds protection.

Skid Pads – A Resilient Nail Barrier

Heavy chipboard sheets can act as protective bottom sheets to defend against nail pops – and as top sheets to protect against stacking damage. Cardboard is no match in wear and toughness when compared with heavyweight chipboard.

When compared with thick paperboard, medium- and high-density fiber boards are more expensive and not recyclable. Additionally, special paper properties of heavyweight chipboard allow moisture resistance to handle the toughest outdoor use cases.

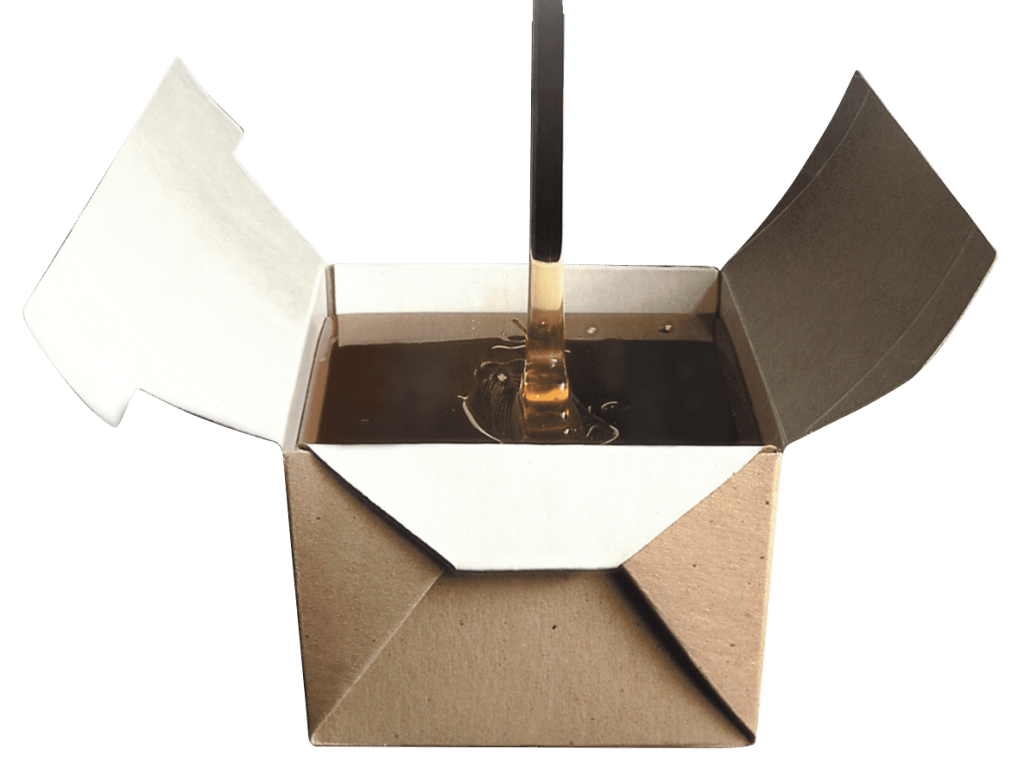

Cold Chain to Hot Melt – Effective in Freezing or Boiling

Dura-Fibre’s thick paperboard is currently playing a critical role in COVID-19 vaccine packaging. Specialty die-cut inserts offer superb freeze/thaw properties for tightly controlled cold chain packaging. At the other end of the temperature spectrum, a custom combination of thick paper supports a long list of customers in the specialty glues and adhesives markets who fill our cartons at temperatures up to 450 degrees.

Thick chipboard, especially when laminated in multiple combinations, is highly versatile. It is shapeable for cartons and specialty packaging. It is strong and tough enough for crates and product protection – all while being cost-effective and sustainable.

Ready to make the switch to thick paperboard products? Contact us today to learn how your organization can save money, prevent damage and improve your environmental footprint with thick chipboard products.

Foam Padded Board

Foam Padded Board Unitized Book Board

Unitized Book Board Laminated Binders Board

Laminated Binders Board Laminated Graphic Board

Laminated Graphic Board Push-Pull Sheets

Push-Pull Sheets Tier Sheets

Tier Sheets Slip Sheets - Single Ply and Laminated

Slip Sheets - Single Ply and Laminated Pallet Sheets

Pallet Sheets Pads - Single Ply and Laminated

Pads - Single Ply and Laminated Poly Coated Paperboard

Poly Coated Paperboard Furniture Back Panels

Furniture Back Panels Trash Compactor Boxes

Trash Compactor Boxes Paperboard Drywall Shims

Paperboard Drywall Shims Paperboard Totes and Containers

Paperboard Totes and Containers Paperboard Crates

Paperboard Crates Paperboard Wraps

Paperboard Wraps Paperboard Cartons

Paperboard Cartons Paperboard Strap Protectors

Paperboard Strap Protectors Paperboard Covers

Paperboard Covers High Caliper C1S and C2S

High Caliper C1S and C2S Heavyweight Folding Boxboard

Heavyweight Folding Boxboard Heavyweight Thru White

Heavyweight Thru White