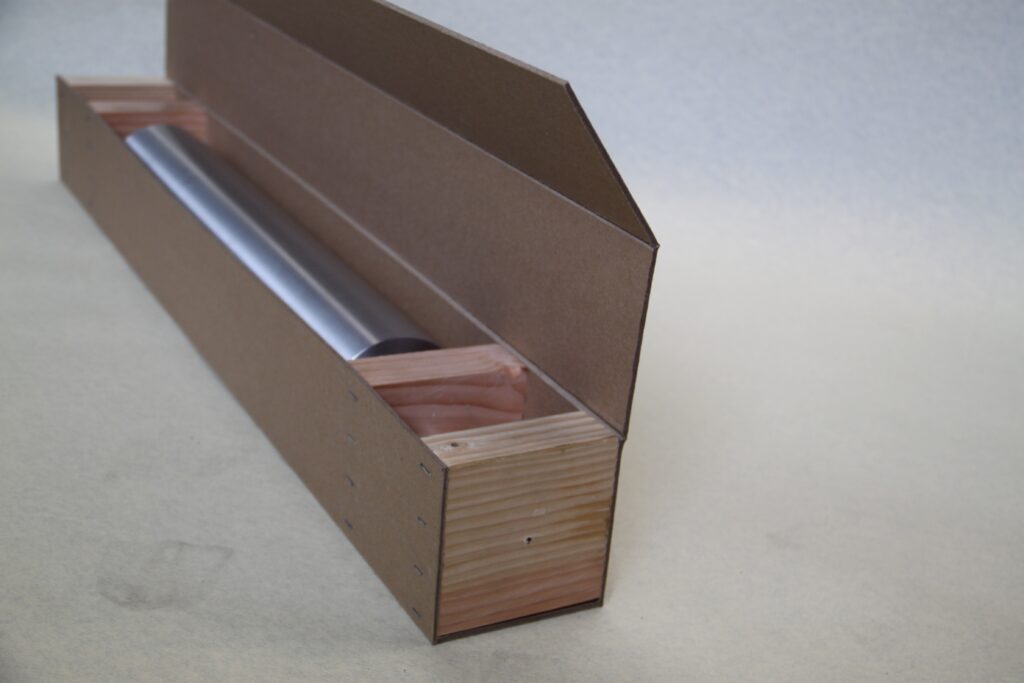

Paperboard crates have become a major success story across a wide range of industrial packaging and crating applications. An early adopter, Metal Manufacturing compared paperboard to wood for packing and shipping bars, pipes and tubes. They found the solution could be achieved much less expensively with paperboard crating as opposed to wood. In particular, the beam strength of paperboard pleasantly surprised these customers as their products greatly exceed typical lengths. Manufacturers of plastic pipes and tubes find paperboard crates to be an even easier fit, given the lighter weights.

Manufacturers Realize Sustainability Benefits From Paperboard Crating

Another high-volume group, Automotive Manufacturing, produces especially large and long parts for trucks and recreational vehicles. They had found that their dealership customers greatly appreciated the ease of recycling paperboard crating instead of sending wood crates to the landfill. These manufacturers also have very long sku lists, and the ability to safely and easily cut down “Mother Crates” to shorter lengths made the space and time required for parts packaging much lower for paperboard crates than wood or plastic alternatives.

Paperboard Crates Outperform Corrugated Across Applications

Even outdoor applications have proven a fit for a long list of manufacturers. For example, a commercial window producer began using Dura-Fibre’s paperboard crates to ship their pieces and parts to apartment and hotel sites. Siding and Paneling manufacturers have found our coated and edge-sprayed crating perfectly suited for their outdoor storage model.

Paperboard solutions work just as well for cartons such as those used in the window fashion industry. These customers have found paperboard better protects against damage than corrugated – especially when shipping direct to consumers. Specialty instruments and devices – especially longer ones – are a great fit. The higher volume production of machine tooling items – metal or plastic – have success in paperboard crating – even specialty hoses and hardline tubing. Conveyor and linear motion systems, custom fencing and railing – the list goes on an on.

OEMs Save Money by Replacing Wood With Paperboard Crating

The problems solved by paperboard crates include reducing the cost pressures caused by high and fluctuating prices of wood, reducing set-up labor, providing lighter shipping weights for lower freight costs, saving space, and improving customer satisfaction.

Dura-Fibre’s packaging engineers are partners in the design process and available to discuss your crating needs. Please contact us for further information.

Foam Padded Board

Foam Padded Board Unitized Book Board

Unitized Book Board Laminated Binders Board

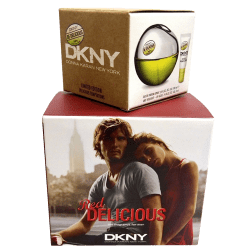

Laminated Binders Board Laminated Graphic Board

Laminated Graphic Board Push-Pull Sheets

Push-Pull Sheets Tier Sheets

Tier Sheets Slip Sheets - Single Ply and Laminated

Slip Sheets - Single Ply and Laminated Pallet Sheets

Pallet Sheets Pads - Single Ply and Laminated

Pads - Single Ply and Laminated Poly Coated Paperboard

Poly Coated Paperboard Furniture Back Panels

Furniture Back Panels Trash Compactor Boxes

Trash Compactor Boxes Paperboard Drywall Shims

Paperboard Drywall Shims Paperboard Totes and Containers

Paperboard Totes and Containers Paperboard Crates

Paperboard Crates Paperboard Wraps

Paperboard Wraps Paperboard Cartons

Paperboard Cartons Paperboard Strap Protectors

Paperboard Strap Protectors Paperboard Covers

Paperboard Covers High Caliper C1S and C2S

High Caliper C1S and C2S Heavyweight Folding Boxboard

Heavyweight Folding Boxboard Heavyweight Thru White

Heavyweight Thru White